Ensuring the safety and cleanliness of our water supply is paramount. Backflow prevention devices are essential tools that protect potable water systems from contamination caused by the unintended reversal of water flow. This reversal can introduce pollutants, chemicals, or pathogens into the drinking water supply, posing significant health risks. In this article, we’ll explore the various types of backflow prevention devices, such as RPZ valves, double check valves, and air gaps, and discuss their functions and applications.

“Clean water is the cornerstone of good health and quality of life.” — Unknown

What Are Backflow Prevention Devices?

Backflow prevention devices are mechanisms installed in plumbing systems to prevent the reverse flow of water, ensuring that contaminants do not enter the clean water supply. These devices are crucial in maintaining water quality and protecting public health. The need for effective backflow prevention is underscored by the growing concerns over water safety and the increasing demand for reliable water infrastructure.

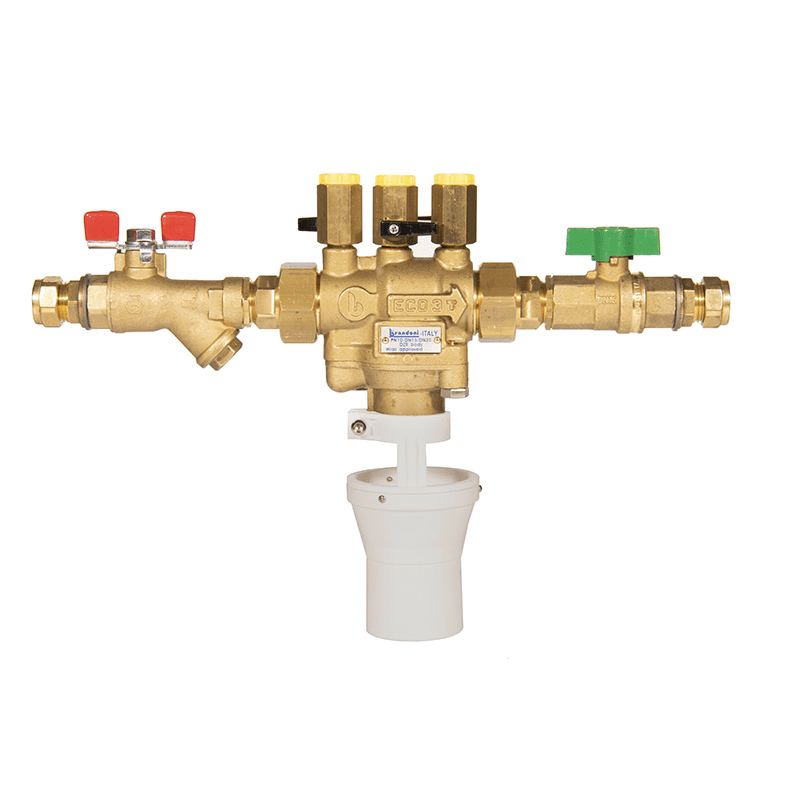

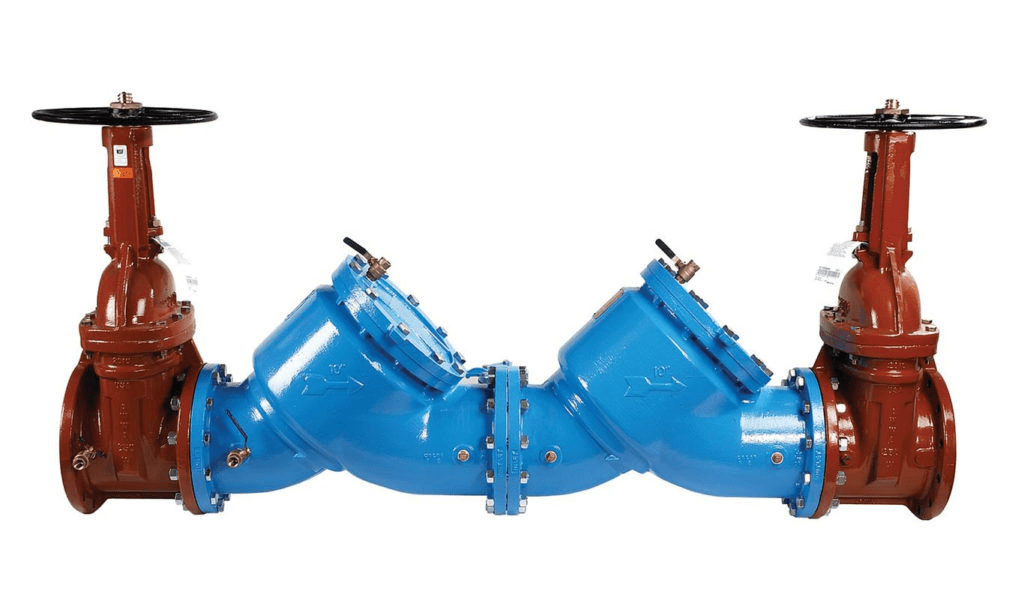

1. RPZ Valves (Reduced Pressure Zone Valves)

How RPZ Valves Work

RPZ valves are among the most effective backflow prevention devices. They consist of two check valves and a pressure relief valve, forming a reduced-pressure zone between the potable water supply and the system. This design allows the RPZ valve to protect against both backpressure and backsiphonage, making it suitable for high-hazard applications.

- Key Features:

- Protects against both backpressure and backsiphonage

- Contains a pressure relief valve that discharges contaminated water

- Typically used in high-risk situations, like commercial and industrial settings

Where RPZ Valves Are Used

RPZ valves are essential for systems where backflow could introduce hazardous substances into the water supply. This includes commercial properties, large irrigation systems, and any location where chemicals, fertilizers, or other hazardous materials are used.

Market Demand

The demand for RPZ valves is growing, driven by stringent regulations and increased awareness of water safety. The global backflow preventers market is projected to expand from USD 422.9 million in 2025 to USD 614.6 million by 2035, reflecting a compound annual growth rate (CAGR) of 3.8% .

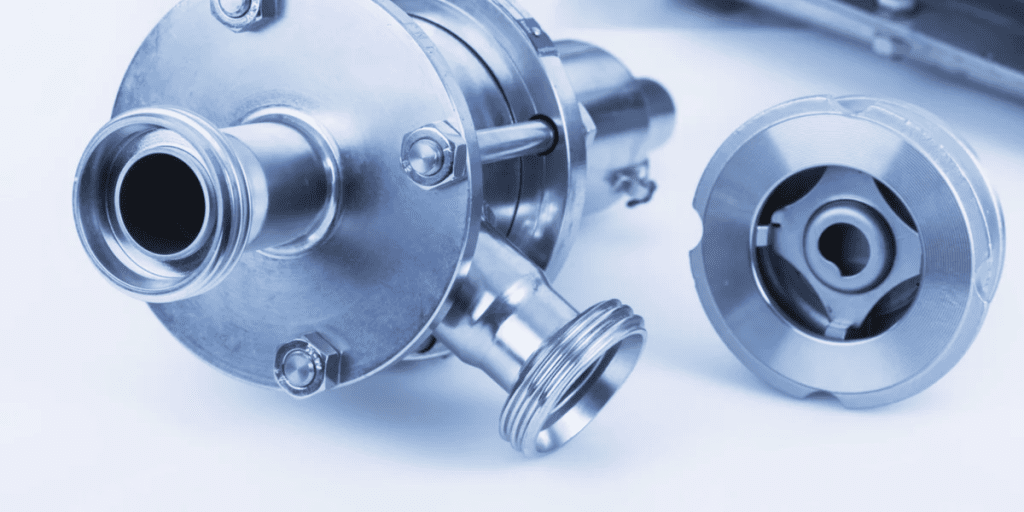

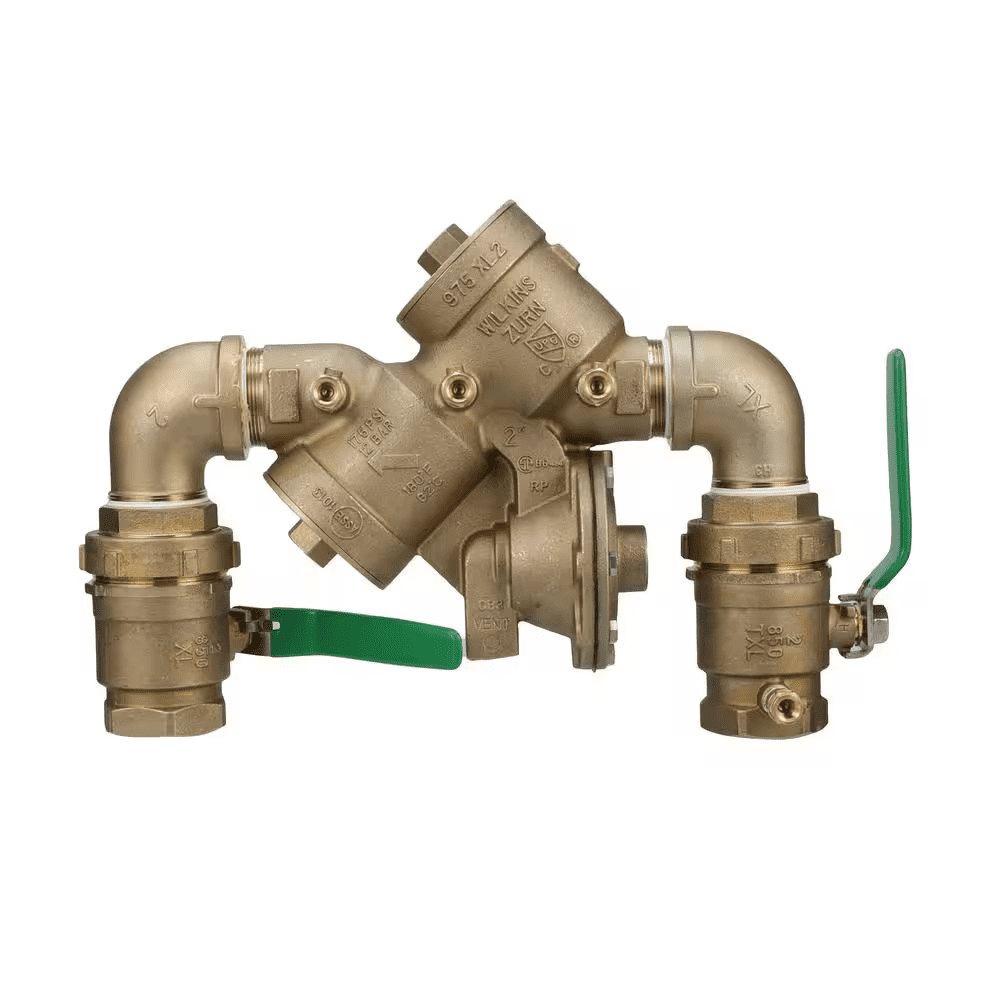

2. Double Check Valves (DCV)

How Double Check Valves Work

A double check valve is a mechanical device consisting of two check valves arranged in series. These valves allow water to flow in one direction and prevent backflow by closing if the water attempts to reverse direction. Double check valves are suitable for low to medium hazard applications.

- Key Features:

- Consists of two check valves arranged in series

- Prevents backflow through a simple, cost-effective design

- Commonly used in residential or commercial settings with lower contamination risk

Where Double Check Valves Are Used

Double check valves are commonly used in applications where the risk of contamination is relatively low, such as in irrigation systems, water supplies for non-potable uses, or in residential homes. They are typically not recommended for high-risk scenarios, such as food processing plants or facilities with hazardous materials.

3. Air Gaps

How Air Gaps Work

An air gap is a physical separation between the water outlet and the flood level of a fixture. This gap ensures that contaminated water cannot siphon back into the potable water supply. Air gaps are the simplest form of backflow prevention and are highly effective when properly maintained.

- Key Features:

- Simple, reliable method of backflow prevention

- Provides an obvious, visible break in the system to prevent backflow

- No moving parts, making it low-maintenance

Where Air Gaps Are Used

Air gaps are most commonly used in residential plumbing systems, such as in dishwashers and water fountains, where a clear space can be maintained between the water supply and the drainage system. They are also used in toilets, bathtubs, and sinks to prevent contamination from backflow.

4. Check Valve vs. Backflow Preventer

While both check valves and backflow preventers serve similar purposes, they are different devices. A check valve is a simple device that only allows water to flow in one direction, preventing backflow. However, check valves do not have the same level of protection as backflow preventers, which are more comprehensive devices designed to handle multiple backflow scenarios, including both backsiphonage and backpressure.

- Key Differences:

- Check valves are a basic form of backflow prevention and are typically used in lower-risk applications.

- Backflow preventers are more advanced and provide comprehensive protection, including devices like RPZ valves, which are required in high-risk applications.

Commercial vs Residential Backflow Prevention

The requirements for backflow prevention devices vary between commercial and residential properties. Commercial backflow preventers are generally more robust and may include RPZ valves or other complex systems to protect against higher contamination risks. Residential backflow preventers, on the other hand, typically involve simpler devices, such as double check valves or air gaps, since the risk of contamination is generally lower.

Commercial Backflow Prevention

Commercial properties, especially those with industrial equipment, chemical storage, or large irrigation systems, require more advanced backflow prevention devices, like RPZ valves, due to the higher risk of contamination. These devices are designed to prevent backflow even in the event of a significant change in water pressure.

Residential Backflow Prevention

For residential properties, the best backflow preventers are usually double check valves or air gaps. These devices are sufficient for protecting homeowners from typical backflow risks, such as those from irrigation systems or household plumbing.

FAQs

1. What is the most effective backflow prevention device?

The most effective backflow prevention device is the RPZ valve. It provides comprehensive protection against both backpressure and backsiphonage, making it ideal for high-risk situations.

2. How do backflow preventers work?

Backflow preventers, such as RPZ valves and double check valves, use check valves or air gaps to stop water from flowing backward into the clean water supply, preventing contamination.

3. Can air gaps be used for all types of backflow prevention?

Air gaps are effective for low-risk applications, such as residential sinks and dishwashers. However, they are not suitable for high-risk situations, such as those involving chemicals or industrial equipment.

4. What is the difference between a check valve and a backflow preventer?

A check valve allows water to flow in one direction, but a backflow preventer is a more comprehensive system that protects against multiple types of backflow risks, such as backpressure and backsiphonage.

5. Do I need a backflow prevention device in my home?

If your home has an irrigation system or connects to a non-potable water source, a backflow prevention device may be required to comply with local water safety regulations.

Conclusion:

Choosing the right backflow prevention devices is crucial for maintaining the safety and quality of your water supply. Whether you’re using RPZ valves, double check valves, or air gaps, each device serves a specific purpose in protecting against backflow. By understanding the different types of backflow preventers and how they function, you can ensure your property is compliant with water safety regulations and help keep the water supply clean and uncontaminated.

Author

-

James is a certified backflow specialist with over 20 years of hands-on experience in plumbing safety.

He’s passionate about educating homeowners and businesses on the importance of clean water systems.

James simplifies complex maintenance tips through clear, practical advice.

When he's not writing, you'll find him inspecting valves or training the next generation of backflow testers.